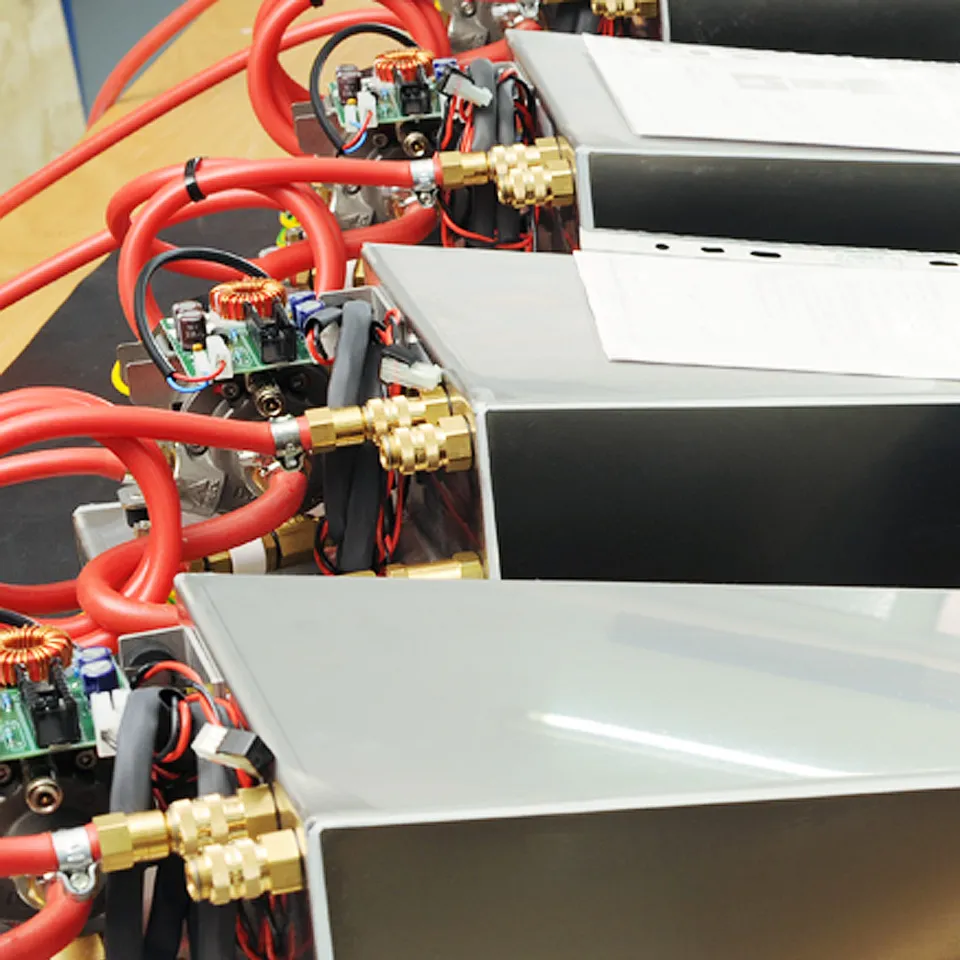

Mechatronic components

rassemblement

Our assembly specialists work strictly according to their assembly instructions and ensure the highest quality workmanship and carry out acceptance tests. Including cable assembly and control cabinet construction

purchasing

According to the required parts list, the purchased parts are purchased worldwide and sent to the assembly process.

We can offer you the following technologies

- Punching/laser cutting:

• Max. raw material 3000 x 1500mm

• Max. material thickness: 6mm - Laser cutting:

• Max. raw material 3000 x 1500mm

• Max. material thickness: 12mm steel - Fiber laser cutting:

• Max. raw material 3000 x 1500mm

• Max. material thickness: 60mm steel - VQC board testing

- Grindingmaster:

• Max. throughput width 1350mm

• Max. flow height 80mm - LVD ToolCell

With auto. Tool change and angle measurement

Of course, we have extensive certificates and the following welding approvals so that your components can be manufactured to the highest standards: DIN 2303 class Q1/Q2 - BK1 to BK4

We can offer you the following connection technologies:

- Hand welding:

• Maximum 3000mm length x 1500mm height x 1500mm readiness (must be checked individually)

• MIG/MAG/WIG - robotic welding (Yaskawa/ Kuka)

• MIG/MAG/ Maximum 2000mm length x 1500mm height x 2000mm readiness (must be checked individually!)

• WIG 750x1000x750 (must be individually tested) - Sanding:

To smooth out joints, we grind the welds. This is necessary to achieve the specified optics. - Glue:

We use the gluing of components when sophisticated design and visible surfaces are required. - rivets:

Titgemeyer MS 50 — blind rivet nut up to M8/blind rivets (shaft diameter max. 3mm)

materials

- aluminum

- steel

- stainless steels

- copper

surfaces

- anodizing

- Phosphating & powder coating

- galvanizing

- More surfaces (e.g. gilding) on request

More technologies in use

- Fixture construction

- Manual roll bending

- eccentric presses

- High-bay warehouse for metal sheets

- PEM nut setting

- spot welding

- stud welding

Do you have any more questions?

At Mey Maschinenbau Prien, cooperation starts with a personal conversation and, if possible, a personal meeting. We would be happy to show you our production facilities in our main plant in Prien am Chiemsee and our plants in Hungary.

We also manufacture machines

Here you can find out how we can implement your machines.